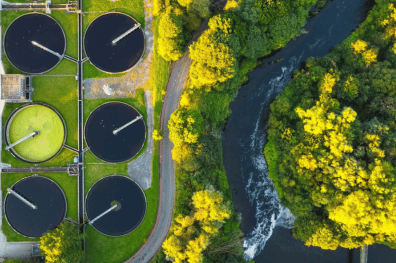

Industrial effluent (3.3 MGD) discharged to a municipal WWTP was being treated with a liquid oxygen diffusion system for the purpose of sulfide control. The liquid oxygen system was unable to control the sulfide in the short retention time available (68% reduction), so the AOTech process was introduced to boost reaction rates, resulting in a 99% reduction in sulfide concentrations.

Industrial Effluent

AOTech technology improved industrial effluent treatment from 68% to 99% sulfide reduction, maximizing short retention windows.

Condensate Underflow

AOTech process eliminated sulfide, thiol, and organic acid odors from a paper mill's 86,000 GPD condensate discharge, solving community concerns.

Oil Water Separator

Discover how AOTech process eliminated H2S and achieved 90% mercaptan reduction in a chemical facility's emulsified waste stream, resolving community odor issues.